模态激振器相关问题

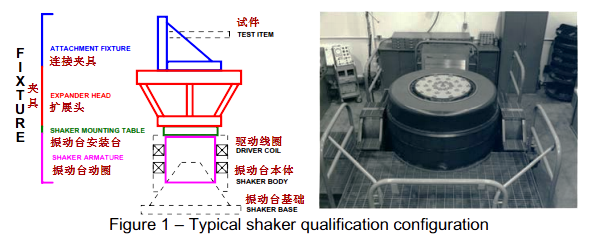

With conventional vibration testing using a shaker with a traditional mounting platform design, the test article is directly attached to the top surface of the armature with some base excitation applied, usually monitored by controlling prescribed acceleration. The device under test (DUT) is normally subjected to an operating environment, generic spectrum or an excessive environment to determine if the equipment is suitable for the intended service. A typical configuration is shown.

对于利用振动台进行传统的振动试验,振动台设计有传统的安装台面。试件被直接连接到动圈的顶面,施加某种基础激励,一般情况下通过控制预先设定的加速度进行监视。被测设备(DUT)通常受到运行环境、常规谱或者超限环境的载荷,来确定设备是否适合于预期的工作。典型布置如下所示:

图1 – 典型的振动台振动品质试验布置

In the early days of modal testing with shaker excitation, smaller shakers were used to apply low level excitation to be able to measure a frequency response function. Usually the shaker was attached with a long rod, commonly referred to as a stinger or quill, in order to impart force to the structure. (The purpose of the stinger was to try to dynamically decouple the shaker from the structure.)

在用激振器激励进行模态试验的早期,为了能够测试频响函数,利用小型的激振器施加小幅值的激励。为了把激振力传递到结构上去,激振器常常连接一根长细杆,一般被称为推力杆或顶杆。(推力杆的用途是要尽量动态地将激振器从结构上解耦开来。)

Because these traditional shakers were typically used for base excitation, the armature attachment configuration was not optimal. Usually, some type of left-right thread arrangement was made or af collar was designed to enable an easier attachment to the shaker. It was a rather difficult arrangement no matter how the connection was made. In addition, thought had to be given to shaker position and actual length of the stinger needed. If a different length stinger was needed, then the shaker needed to be reoriented and realigned as different stinger lengths were used for the modal test. Overall, the set up of the shaker for a modal test was very difficult and cumbersome.

因为这些传统的激振器通常用于基础激励,动圈连接方式不是最优的。通常,进行某种左-右螺栓布置或者设计弹性夹头,以更容易地连接到激振器上。不管如何进行连接,它都是一个相当困难的布置。另外,必须考虑激振器定位和所需推力杆的实际长度。如果需要不同长度的推力杆,那么激振器需要重新确定方向,重新进行对中,因为模态试验用的推力杆长度不同。总体上讲,对模态试验,激振器的设置是非常困难而麻烦的。

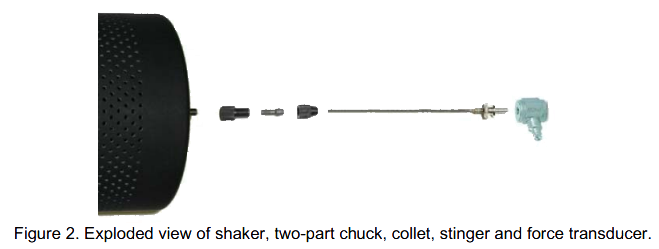

Due to all these problems, thought was given to specific design configurations that were better suited for modal testing applications. This gave rise to the through-hole armature with a chuck and collet design (like gripping a drill bit on a hand drill) that enabled very easy attachment of the shaker to the modal test article. A long stinger can be slid into the shakers through-hole armature, threaded to the force transducer attached to the test article, properly aligned, and then clamped down with the chuck and collet at the appropriate length. These components are shown as an exploded view below and a video demonstrating actual installment is posted at http://www.youtube.com/watch?v=VP_X-8TUtOU[1]. This design also accommodates stingers of different lengths if needed. This arrangement is so simple that it is difficult to imagine having to set up the test without this important feature.

由于这些问题,考虑了更好地适应于模态试验应用的特殊设计布局。带有弹性夹头设计的通孔动圈(类似于手钻中的钻头)应运而生,这可以非常容易地连接激振器到模态试件上。一个长长的推力杆可以滑入激振器的通孔动圈,通过螺纹连接到力传感器上,力传感器连接到试件上,恰当对中后,然后在适合的长度上卡紧弹性夹头。作为分解图的形式,这些部件如下面图2所示。另外,演示实际安装的一个视频可从如下链接查看: http://www.youtube.com/watch?v=VP_X-8TUtOU[1]。如有需要,这种设计同样适合于不同长度的推力杆。这个布置是如此简单,以致于很难想象,如果没有这个重要的功能,该怎样进行试验设置。

图2. 激振器,两体弹性夹头,推力杆和力传感器的分解图

[1]由于国内不方便登录youtube.com,因此将视频发布如下,版权归属modal shop公司: